The first stage after concept selection is product design. This stage includes ergonomics, functionality, technical solutions and realistic product visuals. In this stage, it is necessary for industrial designers and design engineers to work in coordination.

Ergonomics is basically the interaction between the designed product and the user. It ensures that products are conveniently designed for the users.

For example, the easy and firm grip of a toothbrush and its suitability for the shape of the mouth, or the size of a make-up kit that can easily fit into a handbag are all designed considering ergonomic criteria.

As Tulga, we use special softwares to analyze these criteria in our designs. We also experience the physical prototypes we produce directly.

Various materials can be used to produce the parts of the designed product, therefore design should be analyzed from different perspectives and materials should be selected accordingly.

We aim to choose materials that can withstand usage circumstances, easily producible, eco-friendly, visually pleasing, suitable for current and future trends, and cost-effective as well.

At this stage, we are mainly concerned with:

The 2D/3D design sketches created on paper or computer are modelled in 3D with CAD software in real size and with all their details at mechanical design phase.

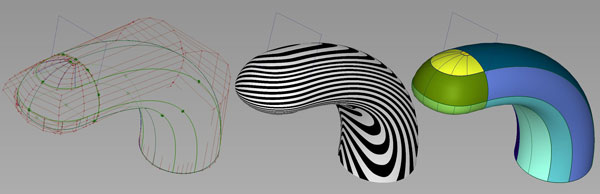

We create the geometric shape we want by using either solid or surface modelling, or both.

We ensure a smooth transition by paying attention to different levels of continuity (G0, G1, G2, G3) in modelling the A surface or visible surfaces of the products.

On the other hand, we build working mechanical systems compatible with the conditions of use and consist of many components that works co-operatively, after examining assembly analysis, operation scenarios, collisions, and strengths through simulation methods and design iterations.

The issues that need to be clarified during mechanical design stage are as follows:

The concept design created during the concept development stage may differ during mechanical design process. The user or the customer should re-evaluate the suitability of the modified exterior appearance.

For this purpose, before we move on to prototyping, we enter color, texture, material, transparency levels of the product designed and the environmental conditions to the computer by rendering method we get photo-realistic images.

Rendering enables us to see the impact of the design on our customers and users. We then update the design if necessary.

The suitability of the product both for Tulga and for our customers is determined in design validation stage after detailing the design. This stage prevents problems that may emerge in future.